Aluminium grade 5052 belongs to 5000 series aluminium sheets. It is popular among our customers. This 5052 aluminium alloy has high strength and easy for you to further process it. It is convenient for you to apply the 5052 aluminium alloy for your production business. Meanwhile, Henan CLIMB Aluminum offer you many specifications for you to choose. Whether for the width, thickness and the temper, you can get the factory price.

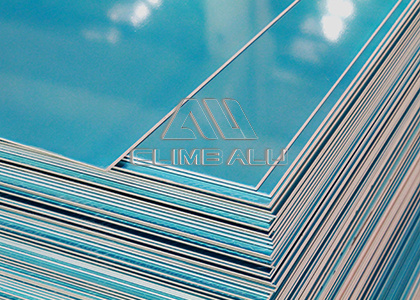

5052 Al-Mg Sheet

Aluminum Alloy No.: 5052

Main ingredients: Aluminium and Magnesium

Available Width(mm): 800-2500

Available Thickness(mm): 0.2-170

Tempers: O-H112

Sample Size: A4 Size

How much do you know about the aluminium grade 5052 sheet properties?

5052 is a type of aluminium magnesium alloy. Its main chemical component is aluminum and magnesium. The 5052 aluminum sheet has high strength, low density and good heat dissipation. At the same time, CLIMB 5052 aluminum plate is corrosion resistant and easy to be welded.

- Aluminum 5052 sheet has high strength and corrosion resistant. Because of the percentage of chemical components of 5052 aluminum alloy, it has higher strength than 3003 aluminum alloy plate. In addition, there is no magnesium component in aluminium grade 5052 plate. This improve the corrosion resistance of 5052 aluminium sheet.

- 5052 aluminum is easy for forming. Its heat deflection temperature is between 420℃ and 475℃. It is convenient for you to forging and die forging. Under this temperature, the deformation rate can be 80%.

- 5052 aluminium plate is machinable. You can machining the 5052 alloy aluminum sheet with copious lubrication at high speed. It is essential for you to utilize sharp tools for cutting.

- It is convenient for you to welding the 5052 alloy aluminium plates by standard techniques. This 5052 aluminum alloy has good performance in gas welding, arc welding, resistance welding, spot welding and seam welding.

[/column]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

5052 Aluminum Sheet A4 Sample

Aluminum Alloy No.: 5052

Main ingredients: Aluminium and Magnesium

Available Width(mm): 800-2500

Available Thickness(mm): 0.2-170

Tempers: O-H112

Sample Size: A4 Size

How to apply aluminium grade 5052 sheet for your business?

CLIMB 5052 aluminum sheets has wide applications in many filed, especially in transportation, if you want to establish a boat building company or automobile factory, 5052 aluminum alloy will be a good choice for your production.

- Because of the corrosion resistance, you can apply CLIMB aluminium grade 5052 for your marine industry. 5052 sheet is a representation of 5000 aluminum sheet plates. 5000 series aluminium has good corrosion resistance. Even though there is saltwater in sea environment, our 5052 aluminum sheets has good anti-corrison performance. Besides, we can also offer you 5083 aluminum marine grade plates for your boat manufacturing. It is also a popular aluminum alloy for ship building among our customers.

- It is applicable for you to manufacturing automobile by using aluminium alloy 5052 plates. Recently, applying aluminum sheet for car production is a trend. Because of its high strength and light weight, the automobile performance has been highly improved. At the same time, the car will be more economic due to the decrease of fuel oil consumption.

Notice for you to further process the aluminium grade 5052

Aluminium grade 5052 has good processability. You can further process our 5052 aluminum plates for your own business. While, do you know the advantages and disadvantages of 5052 aluminum when processing? Here are some notice.

- If you are going to process 5052 alloy aluminium plate by cold stamping, the temper of aluminum sheet will influence the effects. 5052 O is the best temper for cold stamping. Both 5052 h32 aluminum and 5052 h34 aluminium sheets are applicable, too. But the effects will not as good as O temper. It’s worth noting that you had better not cold stamp the 5052 h36 or 5052 h38 aluminum.

- When you weld 5052 alu alloy sheet, it is workable by using gas welding, arc welding, resistance welding, spot welding and seam welding. But the effect of braze welding id better than soft soldering.

- Utilizing 5052 aluminum alloy for machining, it is better for you to machine it in cold hardening condition rather than annealing condition.